Soccer Jersey Printing Types: Vinyl vs. Sublimation vs. Embroidery Explained

When you decide to create a custom soccer jersey, the most important decision isn't just the color or the brand—it’s the soccer jersey printing type.[5] The method used to apply your team crest, player name, and sponsor logo determines how the kit feels, breathes, and, most importantly, how long it lasts.[5]

In this guide, we break down the three industry-standard customization methods to help you choose the best option for your team or collection.

1. Sublimation: The "Gold Standard" of Performance

Sublimation is the technology used for nearly every professional-grade match kit.[5] Unlike other methods that add a layer on top of the fabric, sublimation actually dyes the fibers of the sublimation jersey.[1][5]

The Process: Specialized heat-sensitive inks are printed on transfer paper and then heat-pressed into the polyester.[1] The ink turns into a gas and bonds directly with the fabric molecules.[1][2]Pros:Breathability: Zero added weight or texture; the fabric stays 100% breathable.Durability: The design will never peel, crack, or fade.[1][5][6][7][8] It lasts as long as the fabric itself.[1][3]Design Freedom: Perfect for complex patterns, gradients, and "all-over" prints.[5]Cons: Only works on light-colored polyester fabrics.[9]

2. Heat Transfer Vinyl (HTV): The Classic Personalization

If you’ve ever bought a jersey with a player's name like "Messi 10" on the back, you’ve likely encountered heat press vinyl. This is the most common method for individual customization.

The Process: A thin layer of vinyl is cut into shapes (letters/numbers) and bonded to the surface of the jersey using high heat and pressure.[2]Pros:Versatility: Can be applied to any color or type of fabric.[9][10]Vibrancy: Offers extremely sharp, solid colors and "Pop" that stands out on TV.Affordability: Cost-effective for small orders or single-name sets.[11]Cons: Over time, vinyl can crack or peel if not washed correctly.[1][3][8] It also creates a "solid" patch that can feel slightly heavy on the back.

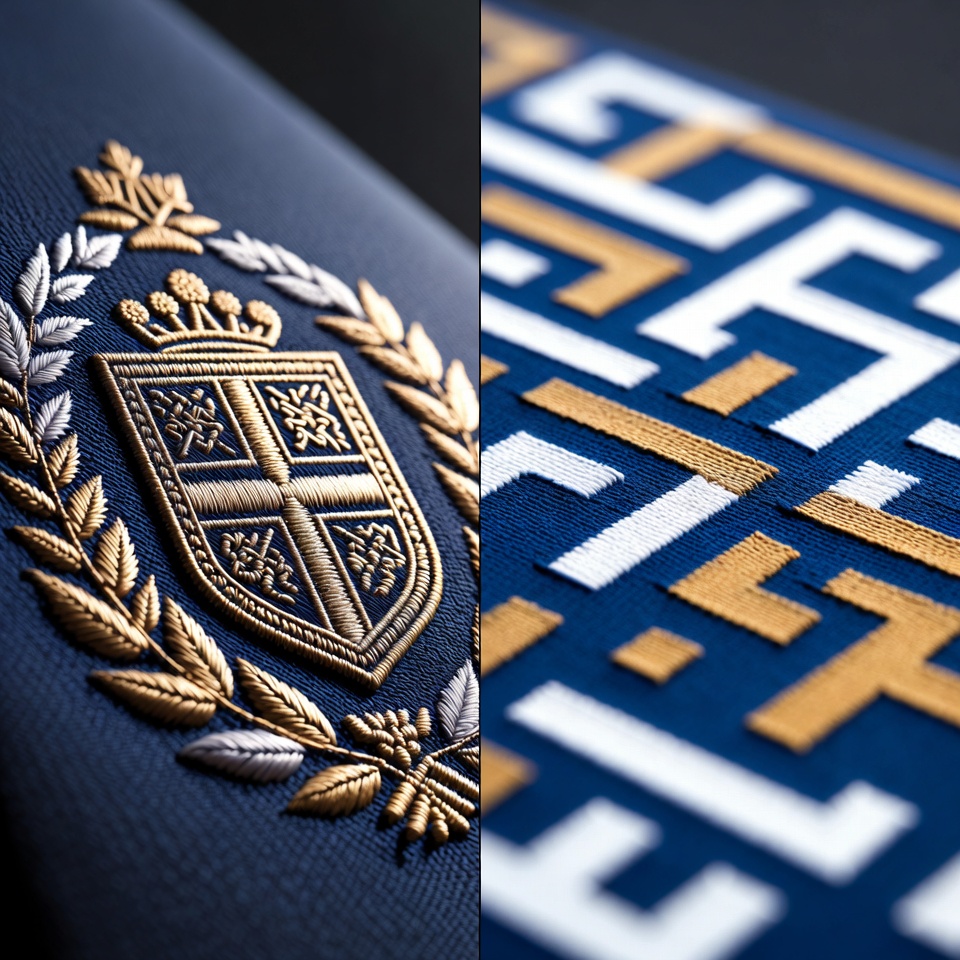

3. Embroidery: The Premium Crest

Reserved almost exclusively for team badges and manufacturer logos (like the Adidas stripes), embroidery adds a touch of prestige and "3D" texture to a custom soccer jersey.

The Process: High-speed industrial machines stitch the design directly into the fabric using thousands of reinforced threads.Pros:Luxury Feel: Gives the kit a traditional, professional, and prestigious look.High Durability: Stitched logos are incredibly resistant to wear and tear.[3][8]Cons: Not suitable for large sponsors or player names as it would be too heavy and scratchy against the skin.

Technical Comparison Table

| Feature | Sublimation | Heat Transfer Vinyl (HTV) | Embroidery |

| Feel | Soft (Part of fabric) | Raised (Smooth film) | Textured (Stitched) |

| Breathability | Perfect | Low (In printed area) | Low |

| Best For | Full Team Kits / Patterns | Names & Numbers | Team Badges / Crests |

| Longevity | Permanent | 50+ Washes (with care) | Very High |

| Complexity | Unlimited (Photos/Gradients) | Simple Logos / Text | Moderate Detail |

Expert Tip: Beware of "Ink Migration"

One of the biggest mistakes in custom soccer jersey production is applying white vinyl numbers to a red or blue sublimated kit. Over time, the dye from the kit can "bleed" into the white vinyl, turning it pink or light blue.

The Solution: At Uitems, we use Sub-Block Vinyl for all our heat transfers. This specialized vinyl has a charcoal-based barrier layer that prevents dye migration, keeping your numbers crisp and white forever.

Maintenance Guide for Printed Jerseys

To maximize the life of your soccer jersey printing types, follow these three golden rules:

Inside Out: Always flip the jersey inside out to protect the vinyl from friction.[7][8]Cold Wash: Never exceed 30°C. High heat melts the adhesive on vinyl and embroidery backings.No Tumble Drying: The heat of a dryer is the #1 killer of soccer jersey prints. Air dry only.